Art:GrainStorage

The software is intended for complex automation of management and real-time quantitative and qualitative accounting at grain (oil) sea and river terminals. It allows organizing the accountancy of operations for acceptance, processing, storage, and shipment of grain efficiently.

Functionality and purpose of subsystems:

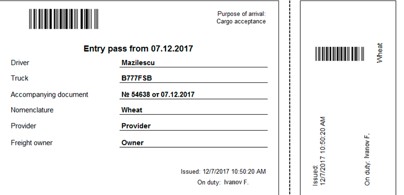

Security control point

-

registration of entrance/exit and accounting of vehicles (auto/railway) at the accumulation places, checkpoints, and the territory of grain storage;

-

elements of «depersonalization» of transport and its subsequent identification using the system of passes (barcoding, QR-coding);

-

the ability to scan copies of incoming documents (consignment notes) from the Art Port with reference to the objects of the system;

-

communication with CCTV cameras: automatic number recognition and photo fixation in the database when the transport enters, when it is weighed, unloaded, leaves;

-

the ability to maintain a blacklist of vehicles, drivers, counterparts;

-

the register of suspicious events and automatic informing of responsible people about them — manual input of weight, vehicles, excess of the rate of the vehicle’s stay in the territory;

-

control of incoming cargoes in the context of suppliers and agreements on allowable quotas;

-

the possibility of communication with the subsystem «Art:Railway station» for automatic filling of data about wagons from the consignment note keeping system of Ukrainian Railways, generation of receiving documents, and wagons residence time control.

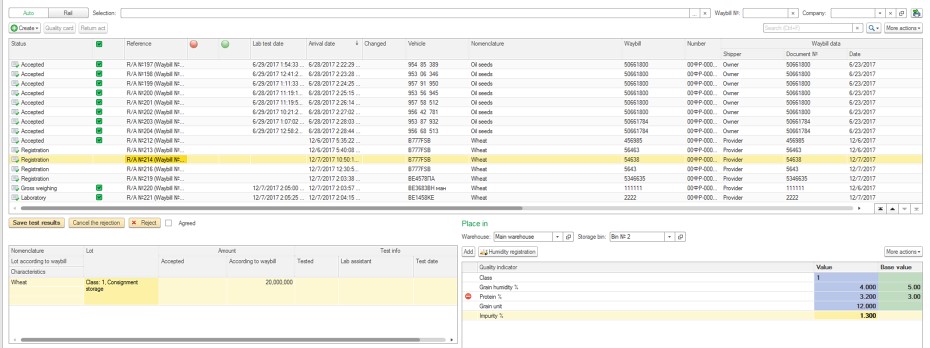

Laboratory

-

flexible adjustment of a set of qualitative indicators for each culture;

-

adjustment of basic indicators as general for the enterprise, and individual for each owner and contract — for culture/class/breed, humidity, degree of impurity;

-

the workstation of the laboratory assistant — setting the visibility of the details of the documents, searching by barcode, registration of rapid tests results, locating the culture, printing of the ticket for weighing, controlling the basis, registering the refusal to accept (full and partial);

-

possibility of automatic averaging of qualitative indicators in reports and in the formation of average daily analyzes;

-

automation of quality setting on lots during the shipment on vessels;

-

visualization of stock availability in the context of quality on the silo tower chart;

-

ability to connect with laboratory equipment to automatically fill the analysis results;

-

complete set of standard reports and printed forms

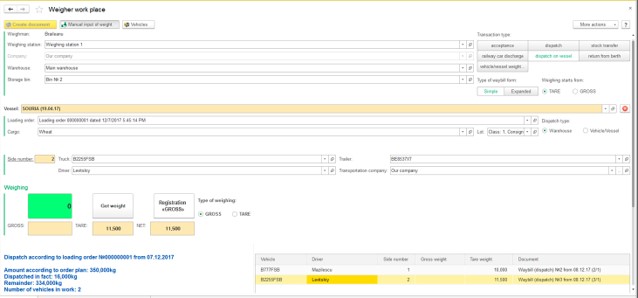

Weighing station

-

Connection with weighing equipment. Photo fixation of weighing operations;

-

Various types of quick search for documents, including the selection by bar code using a scanner or a number recognition of vehicles from CCTV cameras;

-

Control and setting up the weighing operations order and business process stage order as a whole;

-

Identification of the vehicles by side numbers (both in numerical form and in barcode form) for mass weighing operations – cargo transfer, shipment to the vessel by vehicles, unloading the wagon by vehicles;

-

Printing of documents with the possibility of QR-encoding for subsequent registration at the place of shipment (arrival in the berth and departure) using the mobile application of the tallyman;

-

Possibility of separate weighing of the vehicle and the trailer;

-

Control of the execution of orders for shipment/transfer, automatic separation of one consignment note between two orders in case of first-order is done during the wagon weighting;

-

Printing of the stamp with weight and laboratory analysis on the consignment note.

-

Ability to combine the functionality of the weighting station subsystem with the security control point subsystem in case of lack of a workplace at the checkpoint.

Quantitative and qualitative accounting subsystem

-

Ability to keep quantitative and qualitative accounting for the quality of each lot (ZHS-4) and the average daily lab test (ZHS-3), depending on the individual setting of the contract with each client;

-

Automation of the formation of consignment notes registers with the ability to select documents by periods and various details, to group them by owners, contracts and lots, etc., and to separate documents by the limits of quality indicators;

-

Registration of a warehouse receipt with the possibility to pull it into the state register;

-

Re-inventory of the cargo between owners;

- Reflection of part-time work is detailed for each document and, in general, for the register;

-

Formation of acts of calculation and acts of cleaning with automatic filling of turnovers, calculation of regulatory loss, calculation of average holding period;

-

Registration of waste removal and cancellation of aspiration;

-

Registration of the mixing of grain classes;

- A full set of standard reports and printable forms according to Instruction 661

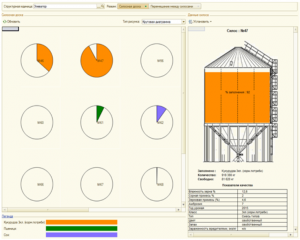

Inventory control

-

Graphic reports «Silo tower chart» for vertical storage and «Remains of cargo» for floor storage;

-

Report on the cargo movement at grain storages and warehouses (ZHS-37);

-

The automated workplace of the shift foreman — the registration of unloading and sealing of empty transport (for oil);

-

Fixation of oil transfer from tank to tank by measuring the level difference and calculating the weight of the load according to the calibration tables, taking into account the cargo temperature and the type of tanks at the beginning and end of the operation;

- Schedule of receipt and shipment of grain (oil);

-

Waste removal;

- Moving between warehouses (silos, containers);

-

Re-inventory;

- The ability to integrate with the terminal’s control system for generating warehouse documents

Implementation:

The system is implemented based on the results of a pre-project survey of the enterprise and the processes that are planned to be automated.

К данной конфигурации пока что нет клиентов.

Art:Forwarding

Art:Forwarding